Wastewater treatment screens are crucial in the wastewater treatment process. They act as the first line of defense, preventing coarse and fine solids from entering downstream systems and ensuring the stability and efficiency of treatment plants.

However, selecting the wrong screen can lead to frequent clogs, increased headloss, and potential damage to downstream equipment. The right choice ensures stable operations, lower maintenance costs, and reliable protection throughout the entire treatment process.

This guide provides an overview of the three main types of wastewater treatment screens, their key design differences, and practical selection criteria.

Main Types of Wastewater Treatment Screens

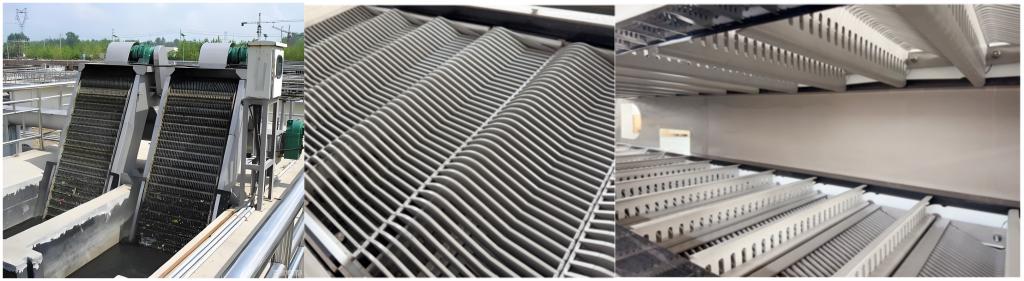

1. Bar Screens

Bar screens are the most traditional and widely used type of wastewater treatment screen. They consist of parallel bars installed either vertically or at an incline, with mechanical raking or step-cleaning mechanisms.

Advantages:

– Strong structural integrity, suitable for handling large debris

– High reliability in harsh operational conditions

– Proven performance in municipal headworks, particularly for high coarse solids loads

Design considerations:

– Bar spacing (typically between 6 and 40 mm)

– Rake mechanism selection (front-cleaned or rear-cleaned)

– Headloss allowance and debris characteristics

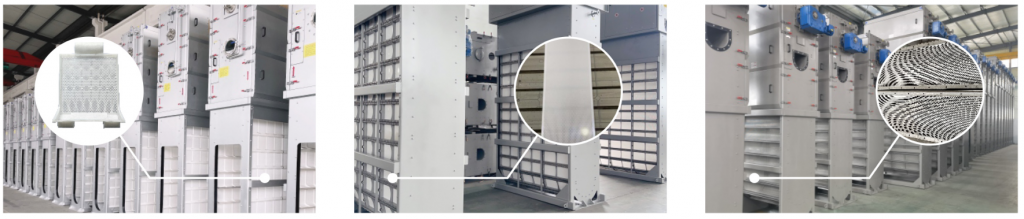

2. Perforated Plate Screens

Perforated plate screens utilize precision-perforated metal plates instead of traditional bars, offering a more advanced screening solution.

Advantages:

– Higher screening efficiency and more uniform separation

– Ideal for compact installations with limited space

– Better suited for finer pre-treatment applications

– Provides smoother flow and reduced turbulence

Design considerations:

– Plate thickness and material grade

– Perforation pattern (round, slotted, or custom)

– Cleaning mechanism reliability and hydraulic loading

3. Rotary Screens (Including Drum Screens)

Rotary screens use a rotating cylindrical screen surface to continuously separate solids from wastewater. These are widely used in both municipal and industrial applications.

Advantages:

– Continuous operation without the need for intermittent raking

– Compact footprint, ideal for space-constrained sites

– Stable performance under variable flow conditions

– Lower headloss compared to static screens

Design considerations:

– Drum diameter and screen opening size

– Rotational speed and drive systems

– Sealing effectiveness (especially for submerged applications)

– Spray washing efficiency and water consumption

Key Selection Factors

Effective selection of wastewater treatment screens depends on several project-specific parameters:

Influent characteristics:

– Flow rate (average and peak)

– Solids size distribution

– Organic vs. inorganic content

Site constraints:

– Channel geometry and dimensions

– Available headloss budget

– Space limitations for installation (indoor vs. outdoor)

Downstream sensitivity:

– Protecting downstream equipment

– Required screening fineness

– Tolerance for occasional breakthrough

Operational requirements:

– Maintenance accessibility

– Operator skill level

– Availability of local spare parts

Common mistake: Often, the decision is made based on price alone. A cheaper screen that clogs frequently or requires constant manual intervention will end up costing more over its lifetime.

How G-LINK Supports Your Screen Selection

G-LINK helps clients navigate the complex process of selecting the right wastewater treatment screens by providing expert guidance and offering a comparative approach. Instead of promoting a single product type, we help you make informed decisions based on your project’s unique requirements.

Our approach:

– Reviewing influent characteristics and hydraulic conditions

– Comparing bar screens, plate screens, and rotary screens from multiple verified OEMs

– Validating technical specifications, materials, and drive configurations

– Bridging communication gaps between your team and Chinese manufacturers

– Supporting quality checks before shipment to avoid any issues upon delivery

This structured process helps you select wastewater treatment screens that balance performance, reliability, and lifecycle cost while minimizing project risks.

Final Thoughts

Choosing the right wastewater treatment screen is crucial for the smooth and efficient operation of any treatment plant. Understanding the differences in screen technology, as well as the specific requirements of your project, is key to making the right choice.

If you’re in the process of selecting screens for an upcoming project, G-LINK is here to help. We offer a full range of wastewater treatment equipment and services to support your project’s success.

Need help? Contact us to discuss your project requirements or explore our comprehensive wastewater treatment solutions.

Related Articles You Might Find Helpful

Sludge Dewatering Technologies: Screw Press vs Belt Press vs Centrifuge

Common Mistakes When Sourcing Wastewater Equipment from China